Hollow crossbeams (iako, kiato, aka) are a good way to save weight without losing strength or stiffness. In the first photo, a 5/8" (16mm) board has been clamped to locater blocks screwed to the workbench. Spacer blocking is glued to the interior surface at regular intervals and importantly where the beam crosses the gunwales of the canoe.

The top member of the beam is another 5/8" thick board and is glued and clamped to the spacer blocks.

Solid blocking at the ama end of the beam is longer to take an inserted dowel later.

1/4" (6mm) or 3/16" (4mm) plywood is glued and nailed (or stapled) to both sides of the beam. After the glue under the first layer of plywood has cured, remove the clamps and put plywood on the other side. I can't remember how much springback there was, but is was not much.

A hardwood dowel (old shovel handle) is glued into the end of the beam for a Wa'apa style connection. The end of the beam will later be finished with several wraps of fiberglass to prevent splitting.

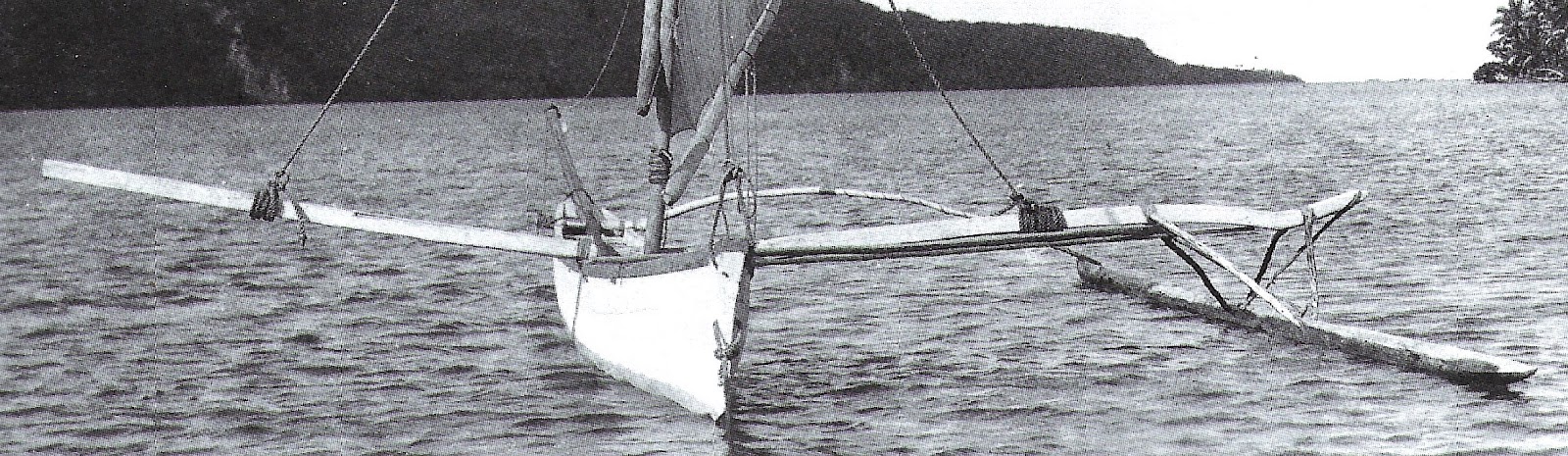

These are the beams I've been using for several years on my Wa'apa canoe.

How much lighter are box beams than their solid counterparts?

ReplyDeleteThanks Gary for this subtle encouragement to build my own box beams :-) I do not regret the extra work it took. That was paid for by the grace of the curvy design and, evidently, by the light strength, since I heard no cracks even when pressed very hard on the morning I had to abort from the Everglades Challenge in huge chop and high wind.

ReplyDeleteDan, I think my solid counterparts were at least twice as heavy as the box beams. I have yet to weigh them. Will try to remember to post the data soon.

ReplyDeleteThis is definitely the method I'll be using for Shan Skailyn's iakos! Thanks for the tip! Are the 5/8" thick boards any wider than what the plans specify in your book? I'm assuming the width and height are the same as the design for the solid wood iakos, right?

ReplyDeleteAs a general rule, I increase the dimensions of a hollow beam by 10% over a solid one.

ReplyDeleteGary, do you fiberglass the whole beam, or just the ends?

ReplyDeleteNormally I just wrap the ends where the dowel goes in to prevent splitting. You can glass the whole beam with light cloth and the paint or varnish will last longer.

ReplyDeleteFor the iakos on the ULUA could you use solid clear cedar boards and steam bend as opposed to laminating? Would this have any disadvantages

ReplyDeleteI would use Alaskan yellow cedar rather than red cedar but I have no idea about the steaming characteristics of cedar. Some woods steam very well like oak and ash but you would have to ask around about cedar.

ReplyDeleteHow about leaving the sides “open”? I’m assuming you would need to glass/epoxy/varnish completely… I think the look would be awesome

ReplyDeleteI believe that the torsional stiffness would be reduced without the sides, however there have been several built by others without sides that are successful.

ReplyDelete