A leeboard at monohull speeds doesn't make much spray, but at multihull speeds can throw up enough spray to get you wet if you're hiked out above and behind it. While you want a blunt radiused leading edge below the waterline, this is not ideal at the water/air interface.

So I've reshaped the leading edge at the waterline area to a sharp knife edge.

Sailing tests yesterday revealed a vast improvement with the board making no fuss at the leading edge. You can still get splashed going into a steep chop where the water hits the upper part of the board, but the improvement in smoother conditions is well worth the modification.

This will work with rudders too although the spray from it will normally stay aft of the crew.

Gary,

ReplyDeleteWhy a blunt leading edge below the waterline? Why not foiled to a sharper leading edge all the way down?

Brilliant! Anything over 6 knots and I am garden-hosed by my leeboard while on the 'proa tack.' Must try this on my new board.

ReplyDeleteA sharp edge for the full depth could cause flow separation and stalling while sailing to windward when leeway is the greatest. See the added illustration at the bottom.

ReplyDeleteHi Gary,

ReplyDeleteGlad to see this post! I stumbled across this idea several years ago, have tried it twice now; completely successful both times. It has the extra benefit of not trying to suck so much air down the foil when there is a (reasonable) angle of attack.

I am confused about one thing: did you sharpen one edge or both? (symmetrical/asymmetrical) The airfoil profile shows just one side ground down.

ReplyDeleteBoth sides are sharpened so it's still symmetrical.

ReplyDeleteHi Gary,

ReplyDeleteJust a couple of issues to think about.

If you are using a symmetrical board consider moving to a laminar flow design that has a find radius on the leading edge and having the maximum cord between 50% and 55% back from the leading edge. The rationale here is that you are driving a narrow hull at relatively high speeds and the laminar flow design produces much less drag than the turbulent flow design you are currently using. At the boat speeds you are looking at there is no down side to this approach Frank Bethwaite pioneered this design back in the 1960s and many faster craft use this design now--Australia II is a famous example of this keel design. I built a laminar flow centerboard for our 16ft skiff many years ago that improved the windward performance by around 25%.

Secondly, if you are using a leeboard on each side of the boat then it would be worth thinking about only shaping one side as this will actually produce lift on the shaped side and potentially improve your windward performance sidnificantly. I'm not sure if a laminar flow design would still work but it's worth considering.

Good luck with your design and development

Scot

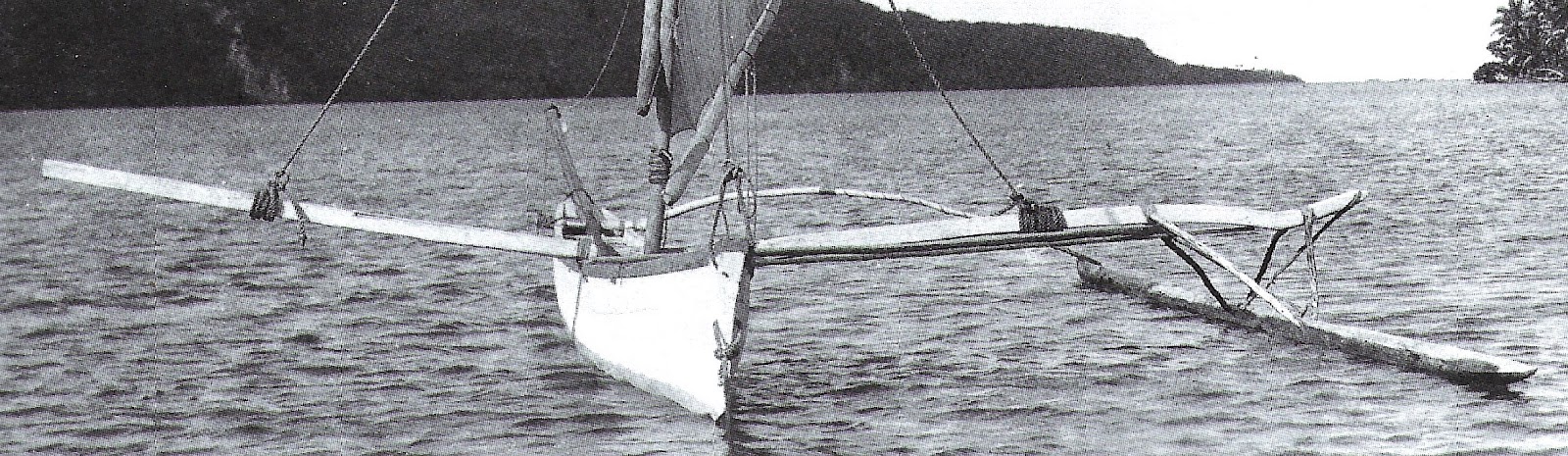

I did exactly the same thing with my (twin) leeboards on my homemade 16' trimarans, and for the same reason. I routinely hit 12-13 mph, and the knife edge above the waterline makes for very quiet and dry sailing. And thanks for your excellent book - Frank (www.DIY-tris.com)

ReplyDeleteGary, will you be offering the plans anytime soon ?

ReplyDeletePlans have been delayed because I've decided on a different rudder system and have yet to test it.

ReplyDeleteWhat do you consider the waterline? - building the Wa'apa and will begin work on rudder soon. Don't know what to expect for freeboard/draft....

ReplyDeleteI would guess about a third of the way up the hull amidships. The sharpening should extend a few inches above and below the waterline.

ReplyDelete