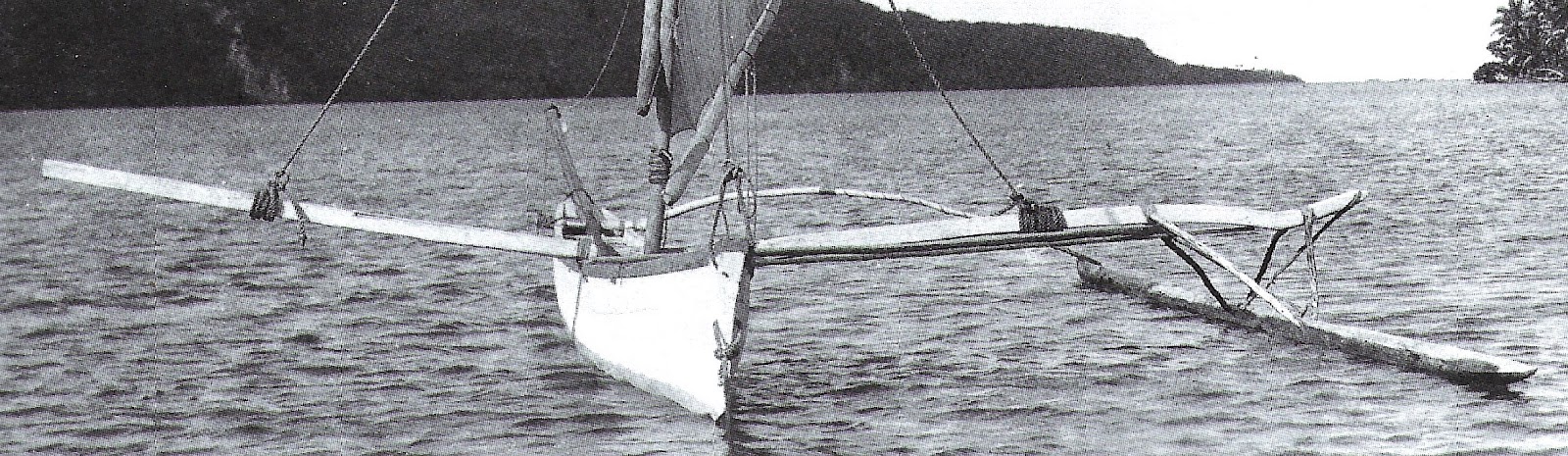

My 15 year old 16' proa, Tarawa, is in the shop for an overhaul and paint. It is in remarkable condition for having spent all of that time out in the weather. The construction is strip planked NZ redwood with epoxy/glass inside and out. It has a self bailing cockpit floor made from a foam sheet with glass both sides. This was the prototype for what was to become the T2 design that I sell. The T2 is two feet longer and has less extreme asymmetry. I will make a new hiking seat that allows the sailor to get his or her weight farther aft. Weight shift is an important part of getting one of these to cooperate with your intentions.

Another boat, along with Harmen's small proa, that inspired us all over some years of proa fantasizing, discussion, and even some building! And of course a testament to the rugged building technique.

ReplyDelete(A funny related story about preservation: for the 2011 Everglades Challenge I was whining about not having time to build a bigger leeboard, and a friend said he had one and would send it. It was a discarded board from an old big proa that had been used to keep his woodpile over the damp ground for the last 10 years. He cut it down and mailed it. Fiberglass and epoxy over wood, it was in perfect shape, which I could clearly see because the cut showed a cross-section of the inner structure).

Already looking much better than when I saw it lying in the grass! I just put away my canoe for winter. Still mulling over the next experiment to try.

ReplyDelete