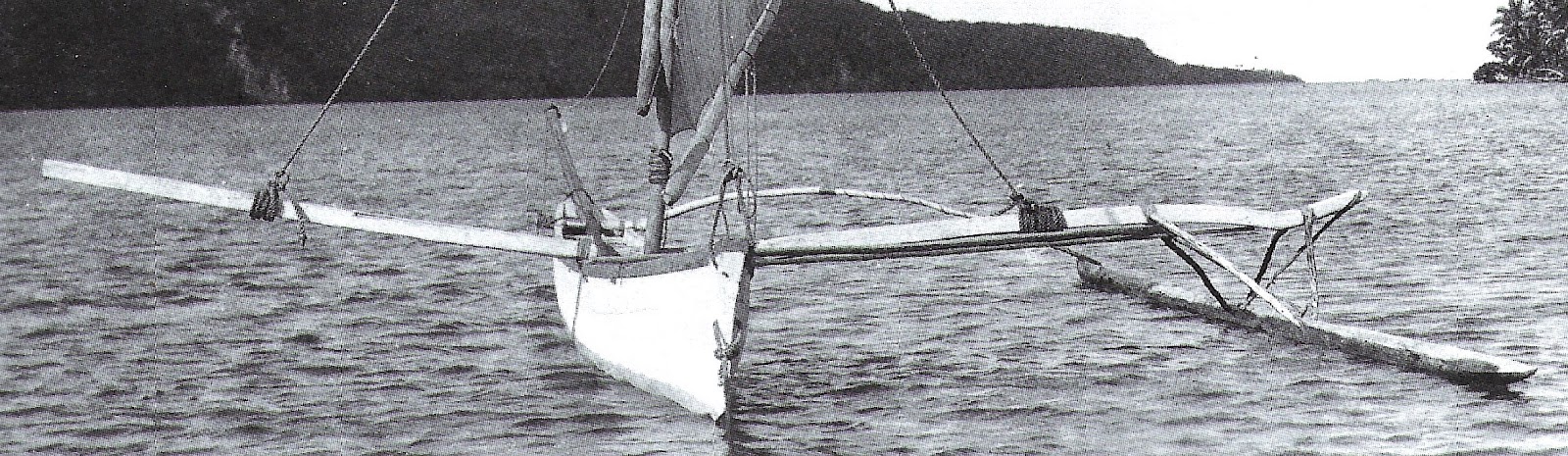

My 16' fifteen year old Tarawa is getting a new ama. The original ama was too small and caused difficulties with more than one person aboard. I had this female strip planking mold hanging in the rafters for a long time which had been used for a custom canoe project. Stripping is not the easiest way to build an ama; I still think foam or ply is faster but the mold was there so I decided to use it. No special timber, just clear 1/4" (6mm) pine planking with square edges. It will be painted so tight edge fitting is not necessary. The shape is symmetrical end to end and top to bottom.

Staples and small nails were used to hold the planks in place. Gorilla glue between the planks.

Three water tight bulkheads divide the ama into four compartments. The inside surface has been sanded and glassed with 6 oz fiberglass and West epoxy.

The second half of the ama has also been stripped, glassed inside and bonded to its other half. Next I will sand the outside, trowel light weight filler in the gaps between the planks, and glass the outside.

This 13.5' (4.1M) ama has twice the volume of the old one. Having the wind die while hiked out won't sink this one.

Nice! I take it the strut architecture is bonded to the outside (doesn't penetrate the hull)?

ReplyDeleteNo, the struts will pass through holes and be attached to the inside base of the hull with a blob of epoxy. A large hard fillet will seal around the entry hole.

ReplyDelete