Many outrigger canoe builders have used PVC drainage pipe as a quick and easy way to build an ama. While not an ideal material, it does float and is cheap and available almost everywhere.

During my construction project in Fiji last year, I found that my ama options were limited; the bamboo wasn't large enough, I couldn't get any Hibiscus (hau, fau, vau) that was the right shape and I didn't want to take the time to build a plywood ama. I could get 6" [150mm] PVC drain pipe and that's what I used.

Shaping the ends was the easy part. The bow was shaped with a cane knife from a section of fence post and the stern just needed a plywood disc siliconed into place.

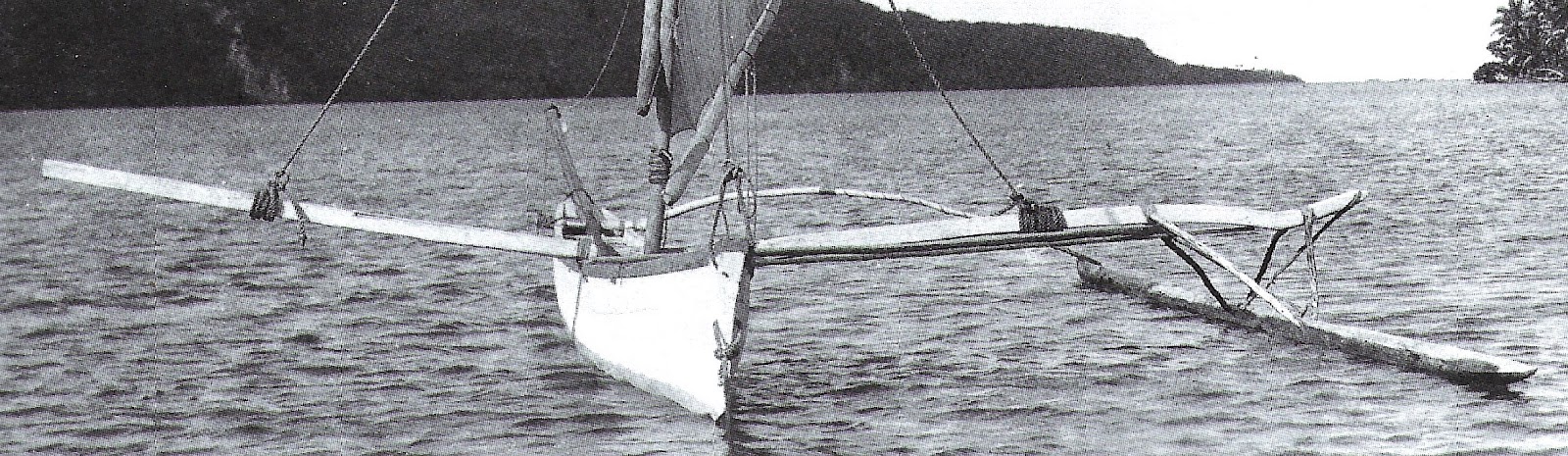

Connecting the ama to the crossbeams is the difficult part and I decided to use an old traditional method that uses several struts at each crossbeam. This method has the advantage of keeping the crossbeam ends well above the water and reducing drag when passing through waves. I didn't want the struts to penetrate the PVC pipe, thinking that this was a potential problem area.

I decided to have the struts fit into holes in a short section of timber 2x4 that was screwed and siliconed to the top of the PVC pipe. The key component of this system is the big lashing that leads straight from the crossbeam to the top of the ama (around and under the section of 2x4). Once I tightened that lashing, everything became amazingly stiff and I found that no amount of wave action caused me any concern.

The lashings were cheap poly rope (which I hate, but I couldn't get anything else) covered with innertube strips to protect the cheap line from the sun.

Ideally an ama would have some rocker to make it more adaptable to different load conditions of the canoe, but mine was pretty straight. If you find a really warped one in the pile, grab it; you might even get a discount.

Great blog. Nice work, did you fill the ama with foam? Are these trips to remote locations intended to reintroduce inhabitants to outrigger canoe building techniques using available materials?

ReplyDeleteDear Sir Gary Dierking

ReplyDeleteI am first captain of Pete Seeger's sloop Clearwater. I have been fired many times for being a pure and good sailor. I can sail nearly anything almost anywhere using skill and humility. Decades ago Pete asked me to build a sailing craft that could be handled only by its crew with no need from machinery. You at long last are part of the answer.

Fondly and sincerely,

Allan

Great Tip. Thanks for sharing. We are actually starting a crazy big project here in a few weeks and will take all the advice we can get. Let us know at Thanks again.

ReplyDeleteMaster Pipe