Having completed my Tamanu in Fiji, and my neighbor John Caldeira having completed his two latest kayaks, we decided to help a local Peace Corps volunteer, John Leonard, build a 16' paddling Wa'apa.

Between the three of us, it was ready for paint after four days. A few details like the stems were changed to the simpler method that I use on the Tamanu. The sheer at the ends was also lowered slightly to make it easier to paddle in the strong winds encountered in the area.

The side panels are 4mm ply and the bottom and deck are 6mm. There is no fiberglass or epoxy used in the structure. Polyurethane glue with bronze boat nails hold the panels together.

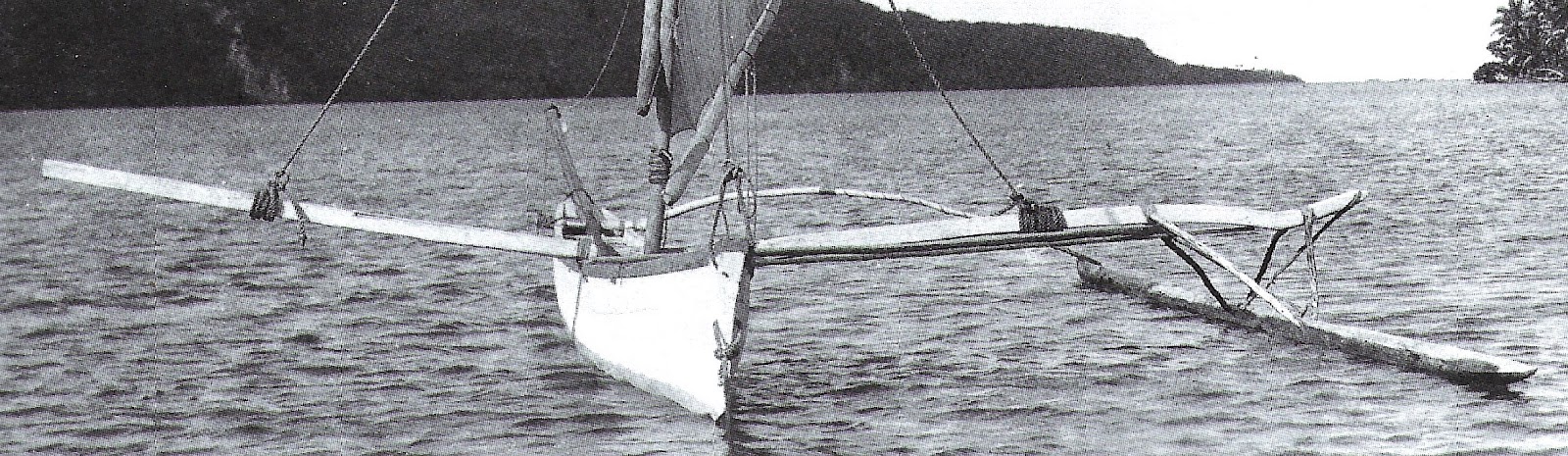

The ama is bamboo with forked sticks providing the connection with the iakos.

Outrigger canoes are easily moved around on the beach with one set of wheels provided you tip it up on its side.

John is paddling from the aft seat but you may want to change to the middle seat when paddling into a strong wind.

John and John held a planned capsize drill immediately after launching. With a low buoyancy ama like this one, you right the canoe by sinking the ama. This helps to empty most of the water from the hull as it is rolling back upright.

The extra bamboo above the ama provides secondary buoyancy if the ama is pushed under the water.

The deck hatches are made from the tops of square plastic containers with snap on lids.

John reports that the canoe has already caught many fish and is a definite chick magnet.

That is brilliant, Gary. I have purchased your book and am getting ready to build the Wa`apa myself, but am curious about the new stem design. Do you have any details available on that, apart from the Tamanu plans?

ReplyDeleteRather than a inner and outer stem, The side panels have a 1.5"x3/4" board attached and beveled to fit the other panelside. These are glued and screwed to one another to form the inner stem. On my Tamanu, I rounded off the whole mess into a pleasing semi-circular profile and fiberglased the bow and stern--but it's not really necessary as this one shows. It's quick and easy!

ReplyDeleteDan

The stem was made as Dan says, with the stem split into two halves and each attached to a hull side before the fold-up. We did still add an outer stem however. While not structurally important, it did cover the edge grain of the plywood sheets. This is important if you're not using any epoxy or glass for sealing.

ReplyDeleteExcellent- That does sound nice and easy. I think I would add an outer stem piece also, for greater durability in beaching, etc. Thanks for the info, Dan and Gary.

ReplyDeleteGary- Do you ever make it back here to Hawaii anymore?

Hey Gary. This is John Leonard. I just wanted to say that I'm having a great time paddling the Dadakulaci. It does well even in strong winds, and I've been using it to explore some of the outer reefs in my area. It is a big hit with the villagers.

ReplyDeleteI wonder how well this has survived during the last 6 years. For me, there is something 'earthy' about using nails and glue rather than 'vast' quantities of epoxy resin/fibreglass etc.. I guess you would have to be more accurate in shaping/joining the various parts? and be very careful with end grain. It would be interesting if there was much weight difference. I have 'the book' and am thinking of building the Wa'apa using Gaboon marine ply but am now unsure whether to go the epoxy free route?! .... maybe with a couple of sacrificial wood strips/runners on the underside of the hull? Any thoughts would be welcome. In the meantime thanks for a most interesting and informative blog. Greetings all, from the UK.Nev.

ReplyDeleteI think the longevity of a no-epoxy canoe will depend on how it's being stored when not in use. Sitting right side up out in the sun and rain will give it a short life. Stored in a shady well ventilated dry area, it could be around for the next 25 years.

ReplyDeleteI did increase the thickness of the bottom plank on mine because there was no fiberglass.