I've built a mockup of my Va'a Motu's forward crossbeam and am using 1/8" (3mm) plywood in place of the stainless steel plate I will use on the real hinge.

The beam is hollow with 3/4" (19mm) timber top and bottom with 1/4" (6mm) ply on the sides. The timber on the Va'a Motu beam is actually two layers of 3/8" laminated together.

I drew a careful line where the beam will be cut and glued on two 1/8" plywood spacers that allow the hinge parts to slide past each other.

The 1/8" ply pieces that you see will be stainless steel plate and the fiberglass pins will be 5/16" stainless. I drilled pilot holes for the fasteners to make sure that the beam stays straight when it is reassembled.

I cut the beam in half with a thin kerf pull saw.

A bulkhead and side blocking to a depth of 4" (100mm) are glued into the cut ends of the beam to reinforce it.

And there it is. It seems stable enough for the job, so I'll hunt down some stainless plate and get to work on the real thing.

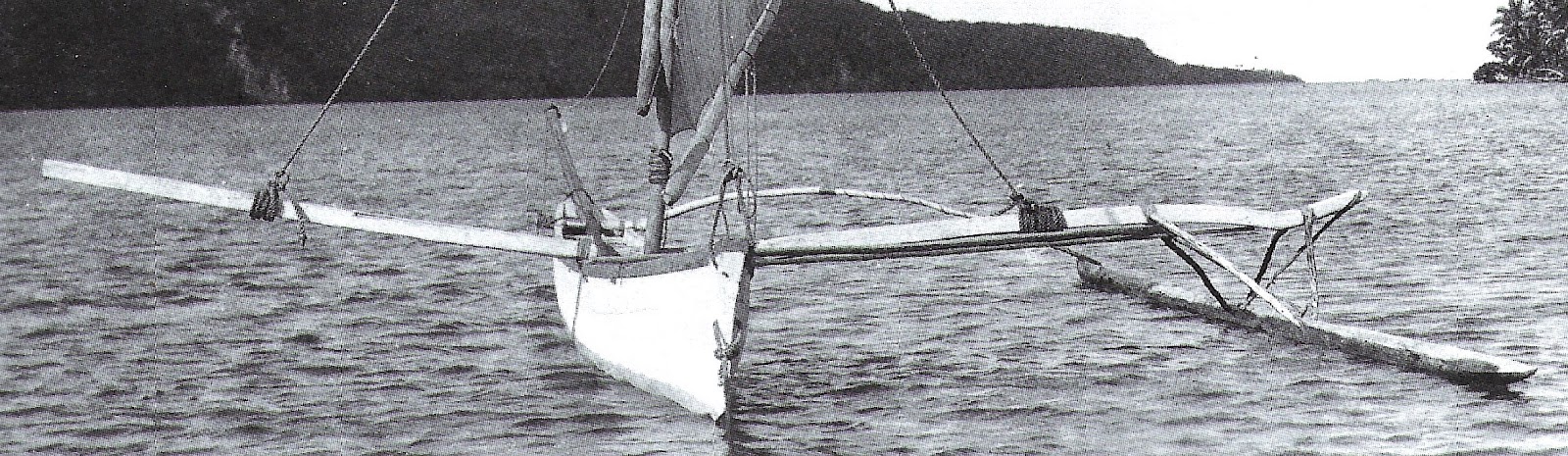

I'm interested in building an outrigger like yours--perhaps around 25 feet.

ReplyDeleteDo you know where I could get plans for the hull and outrigger?

Best,

Scot.

Nice idea! I have generally not been interested in hinging or folding systems that did not include considerable overlap of sliding tubes, etc., but this hinge seems like it would work fine (and for minimum weight), especially as I guess it would be used to fold only the end 3 or 4 feet of the ama-to-akas where stresses are not so bad.

ReplyDeleteThe Wa'apa is 24' and the Ulua can be stretched to 27'. Visit:

ReplyDeletehttp://gary.dierking.net

I've located the hinge point as far outboard as possible while still staying under the legal trailering width.

ReplyDeleteoutrigger porn gary, with her ankles tucked behind her ears like that, bet shes a fun ride.

ReplyDeleteGary, I'm trying to figure out why you recessed the watertight bulkheads inside, rather than flush with the ends. Do you mind sharing your reasoning there?

ReplyDeleteThanks

Geoff

The bolts along the center of the beam have nuts inside, so I needed access to the ends of the bolts.

ReplyDelete